SHANZHONG IRON AND STEEL (SHANDONG) CO..LTD.

High Carbon Spring Tempering Steel Wire

Classification :

PRODUCT DETAILS

High Carbon Spring Tempering Steel Wire Description

High carbon steel is used to make spring tempered carbon steel wire. Commonly used grades of spring steel wire do not have a specific chemical name, such as 1065 or 1080, which is common in other types of high carbon steel products. Rather, they are specified and manufactured according to performance criteria specific to their primary end use, I .e., the manufacture of coil springs. These performance standards allow a range of carbon content, but there are other factors, such as tensile strength and bending/winding tests must be met within the specified range.

Mainly Divided Into Three Categories:

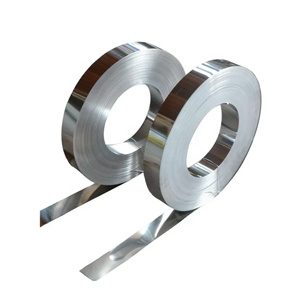

hard pull spring steel wire:Also known as HDMB spring wire, it is a cost-effective choice for many general-purpose applications. The carbon content ranges from 0.45 to 0.85 percent. Since it is usually not heat-treated after drawing, it has high strength and medium toughness. It is available in a variety of diameters and is manufactured in accordance with ASTM A227 (uncoated finish) and ASTM A764 (galvanized finish).

oil tempered spring steel wire:Also known as OTMB spring steel wire, it is an excellent general-purpose spring steel wire with improved performance compared to hard drawing. The carbon content ranges from 0.55 to 0.85 percent. After drawing, the oil-tempered wire rod is subjected to heat treatment and controlled cooling in an oil bath to increase its toughness while maintaining high tensile strength. This makes it particularly suitable for applications requiring high impact resistance or a large number of deflection cycles. Oil tempered spring steel wire is available in a variety of diameters and is manufactured in accordance with ASTM A229. This grade does not provide a galvanized finish.

music spring high quality steel wire:Also known as music wire or piano wire, it is a very high quality steel wire suitable for demanding applications. The carbon content ranges from 0.70 to 1.00 percent. The music wire is heat treated after drawing to relieve stress and toughen the wire while maintaining high tensile strength. The strings are typically 0.250 inches or less in diameter and are manufactured in accordance with ASTM A228. It has a variety of surface treatments to choose from, such as bright, phosphate, tin and zinc.

Scope of Application

Steel wire is widely used in the manufacture of many wire products.

Packing and delivery

It relies on its product, price, service and location advantages to establish long-term cooperation with many clients in North America, South America, Europe, Southeast Asia, the Middle East and Africa, and has established a business foundation in Peru, the Philippines, Russia and elsewhere.

FACTORY APPEARANCE

Factory Workshop

Factory Workshop

Factory Workshop

Factory Workshop

Factory Workshop

Factory Workshop

HONOR

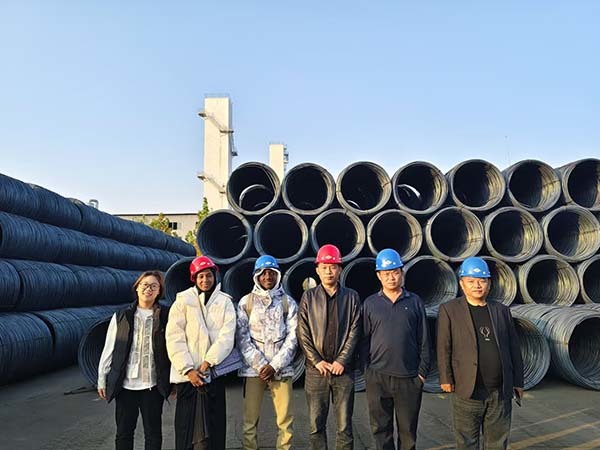

CUSTOMER VISIT

FAQ

Once the products received by customer were found not comply with the products or contract demands, what will you do?

Do you provide samples Is it free or extra?

What certifications do your products have?

What kind of payment terms would you accept?

What is the delivery time?

What is your MOQ?

RELATED PRODUCTS

GET A FREE QUOTE