SHANZHONG IRON AND STEEL (SHANDONG) CO..LTD.

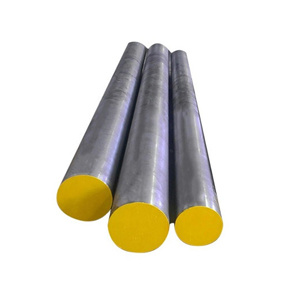

AISI/SAE 5160 Carbon Steel Bar

Classification :

PRODUCT DETAILS

AISI/SAE 5160 Carbon Steel Bar Description

Steel is a versatile material. One steel alloy is AISI 5160, which is an American Society for Testing and Materials (ASTM) designation for spring steel.

Product Parameters

|

Product Name |

AISI/SAE 5160 Carbon Steel Bar | |||

|

Standard |

EN/DIN/JIS/ASTM/BS/ASME/AISI, etc. |

|||

|

Common Round Bar Specifications |

3.0-50.8 mm, Over 50.8-300mm |

|||

|

Flat Steel Common Specifications |

6.35x12.7mm, 6.35x25.4mm, 12.7x25.4mm |

|||

|

Hexagon Bar Common Specifications |

AF5.8mm-17mm |

|||

|

Square Bar Common Specifications |

AF2mm-14mm, AF6.35mm, 9.5mm, 12.7mm, 15.98mm, 19.0mm, 25.4mm |

|||

|

Length |

1-6meters, Size Accept Custom |

|||

|

Diameter(mm) |

Hot Rolling Round Bar |

25-600 |

Cold Rolling Square Bar |

6-50.8 |

|

Hot Rolling Square Bar |

21-54 |

Cold Rolling Hexagon Bar |

9.5-65 |

|

|

Cold Rolling Round bar |

6-101.6 |

Forged Rebar |

200-1000 |

|

|

Surface Process |

Bright, Polished, Black |

|||

|

Other Services |

Machining(cnc), Centerless Grinding(cg), Heat Treatment, Annealing, Pickling, Polishing, Rolling, Forging, Cutting, Bending, Small Machining, etc. |

|||

Chemical Composition

|

Standard |

Grade |

C |

Si |

Mn |

Cr |

V |

P≤ |

S≤ |

|

DIN 17221 |

60SiCr7 |

0.57-0.65 |

1.50-1.80 |

0.70-1.00 |

0.20-0.40 |

|

0.030 |

0.030 |

|

55Cr3 |

0.52-059 |

≤ 0.40 |

0.70-1.00 |

0.70-1.00 |

|

0.025 |

0.025 |

|

|

60Cr3 |

0.56-0.64 |

0.17-0.37 |

0.70-1.00 |

0.70-1.00 |

|

0.025 |

0.025 |

|

|

50CrV4 |

0.47-0.55 |

0.15-0.40 |

0.70-1.00 |

0.70-1.10 |

0.10-0.20 |

0.030 |

0.030 |

|

|

JIS G4801 |

SUP6 |

0.55-0.65 |

1.50-1.80 |

0.70-1.00 |

— |

|

0.035 |

0.035 |

|

SUP7 |

0.55-0.65 |

1.80-2.20 |

0.70-1.00 |

— |

|

0.035 |

0.035 |

|

|

SUP9 |

0.52-0.60 |

0.15-0.35 |

0.65-0.95 |

0.65-0.95 |

|

0.030 |

0.030 |

|

|

SUP9A |

0.56-0.64 |

0.15-0.35 |

0.70-1.00 |

0.70-1.00 |

|

0.030 |

0.030 |

|

|

SUP10 |

0.47-0.55 |

0.15-0.35 |

0.65-0.95 |

0.80-1.10 |

0.15-0.25 |

0.030 |

0.030 |

|

|

SAE J1268 |

9260/H |

0.55-0.65 |

0.70-1.20 |

0.65-1.10 |

≤0.2 |

|

0.040 |

0.030 |

|

5155 |

0.50-0.60 |

0.15-0.35 |

0.65-1.10 |

0.60-1.00 |

|

0.040 |

0.030 |

|

|

5160/H |

0.55-0.65 |

0.15-0.35 |

0.65-1.10 |

0.60-1.00 |

|

0.040 |

0.030 |

|

|

6150 |

0.47-0.54 |

0.15-0.35 |

0.60-1.00 |

0.75-1.20 |

≤ 0.15 |

0.040 |

0.030 |

Mechanical Properties

|

Standard |

Heat Treatment |

Mechanical Property [≥] |

|||||||

|

GB |

SAE |

JIS |

DIN |

Quenching Temprature°C |

Quenchant |

Temper Stressing°C |

Tensile Strength Rm/[N/mm2] |

Yield Strength ReL/[N/mm2] |

HBW≤ |

|

65Mn |

1066 |

- |

- |

830 |

Oil |

540 |

980 |

785 |

302 |

|

60Si2Mn |

9260 |

SUP6 |

60Si7 |

870 |

480 |

1275 |

1180 |

321 |

|

|

60Si2MnA |

9260 |

SUP7 |

60Si7 |

870 |

440 |

1570 |

1375 |

321 |

|

|

55CrMnA |

5155 |

SUP9 |

55Cr3 |

830-860 |

460-510 |

1225 |

1080(Rpo 2) |

321 |

|

|

60CrMnA |

5160/h |

SUP9A |

- |

830-860 |

460-520 |

1225 |

1080(Rpo 2) |

321 |

|

|

50CrVA |

6150 |

SUP10 |

51CrV4 |

850 |

500 |

1275 |

1130 |

321 |

|

Scope of Application

5160 steel is an ideal spring steel. Its high strength is often used in applications with small cross-sections under significant stress, such as springs, fasteners, and leaf springs in automotive suspensions.

Packing and delivery

It relies on its product, price, service and location advantages to establish long-term cooperation with many clients in North America, South America, Europe, Southeast Asia, the Middle East and Africa, and has established a business foundation in Peru, the Philippines, Russia and elsewhere.

FACTORY APPEARANCE

Factory Workshop

Factory Workshop

Factory Workshop

Factory Workshop

Factory Workshop

Factory Workshop

HONOR

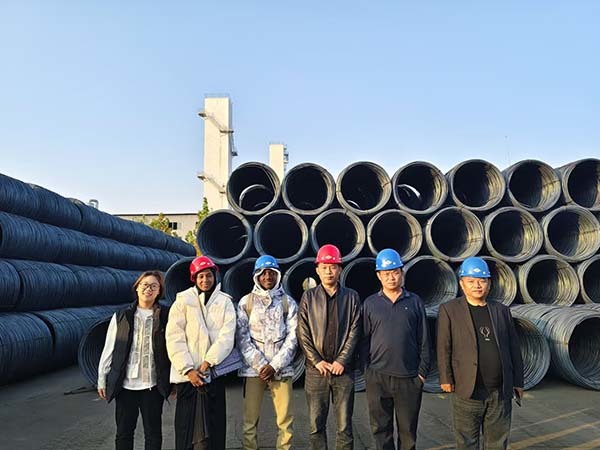

CUSTOMER VISIT

FAQ

Once the products received by customer were found not comply with the products or contract demands, what will you do?

Do you provide samples Is it free or extra?

What certifications do your products have?

What kind of payment terms would you accept?

What is the delivery time?

What is your MOQ?

RELATED PRODUCTS

GET A FREE QUOTE